Alloy Fluxing onwe ya na eyi na mgbochi corrosion

Nkọwa

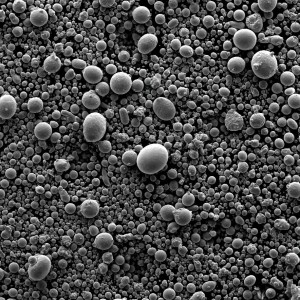

NiCrBSi usoro alloy ntụ ntụ nke nwere isi ike dị elu bụ nke a na-ejikarị na-eyi na-eguzogide ọgwụ na corrosion eguzogide alloy ntụ ntụ nwere obere agbaze na ntụ ntụ na-agbaze okpomọkụ.Ọ nwere ọmarịcha onwe fusibility, wettability na ịgba ịgbado ọkụ arụmọrụ.A na-ejikarị ya eme ihe na-eguzogide corrosion na eyi na-eguzogide ọgwụ, karịsịa maka mgbochi mgbochi na nrụzi nke akụkụ ndị na-eguzogide iyi.

Ngwaahịa ndị yiri ya

| Ụdị | Aha ngwaahịa | AMPERIT | METCO/AMDRY | WOKA | PRAXAIR | PAC |

| KF-Ni15 | NiCrBSiFe | |||||

| KF-Ni25 | NiCrBSiFe | |||||

| KF-Ni35 | NiCrBSiFe | 12 | NI563 | 65 | ||

| KF-Ni45 | NiCrBSiFe | 14 | 69 | |||

| KF-Ni55 | NiCrBSiFe | |||||

| KF-Ni60B | NiCrBSiFe | |||||

| KF-Ni60A | NiCrBSiFe | 335 | 15/2001 | NI167 / 1275 | 60 | |

| KF-Ni60AA | NiCrBSiFe | 335 | 15/2001 | NI167 / 1275 | 60 | |

| KF-300A | Ni60+35WC-Ni | 36/734 | WC562 | 81 | ||

| KF-300B | Ni60A+50WC-Co | 34/734 | WC487 | 89 | ||

| KF-300C | Ni60+35WC-Co | |||||

| KF-300D | Nikel base Tugsten Carbide na-agbapụta onwe ya |

Nkọwapụta

| Ụdị | Aha ngwaahịa | Chemistry (wt%) | Isi ike | Okpomọkụ | Njirimara & Ngwa | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| C | Cr | Si | Fe | B | Ni | |||||

| KF-Ni15 | NiCrBSiFe | 0.15 | 5 | 2 | 5 | 1 | Bal. | HRC 15 | ≤700ºC | • Oxy-Acetylene, PTA, HVOF, APS, laser cladding, onwe-fluxing, okirikiri. • Mpempe iko, bearings • Ala ike, elu siri ike • Ezigbo nguzogide corrosion na wetability |

| KF-Ni25 | NiCrBSiFe | 0.20 | 7 | 2.8 | 5 | 1.5 | Bal. | HRC25 | ≤700ºC | • Oxy-Acetylene, PTA, HVOF, APS, laser cladding, onwe-fluxing, okirikiri. • Mpempe iko, bearings • Ala ike, elu siri ike • Ezi oxidation na corrosion eguzogide yana wetability • Machinability mara mma |

| KF-Ni35 | NiCrBSiFe | 0.30 | 9 | 3 | 5 | 2 | Bal. | HRC 35 | ≤ 650ºC | • Glass ebu , bearings • Piston • oche Valve |

| KF-Ni45 | NiCrBSiFe | 0.45 | 13 | 3 | 10 | 2.5 | Bal. | HRC45 | ≤ 650ºC | • Glass ebu , bearings • Piston • oche Valve |

| KF-Ni55 | NiCrBSiFe | 0.75 | 15 | 3 | 10 | 3 | Bal. | HRC 55 | ≤ 650ºC | • Ebu • agba • Piston |

| KF-Ni60B | NiCrBSiFe | 0.80 | 17 | 4 | 15 | 3.5 | Bal. | HRC60 | ≤ 650ºC | • Akara agba • Ọkpụkpọ ọkpọkọ • Piston |

| KF-Ni60A | NiCrBSiFe | 0.80 | 17 | 4 | 5 | 3.5 | Bal. | HRC 60 | ≤ 650ºC | • Oxy-Acetylene, PTA, HVOF, APS, laser cladding, onwe-fluxing, okirikiri. •Pistons, ibugharị rollers, waya ịse wiil na-adọkpụ, ịghasa extrusion • Akwa isi ike, eyi na nguzogide corrosion |

| KF-Ni60AA | NiCrBSiFe | 0.90 | 17 | 5 | 3 | 3.5 | Bal. | HRC60 | ≤ 650ºC | • Njikọ mmanụ • ihe nfefe • Wire ịbịaru wiil na-adọkpụ, • ịghasa extrusion |

| KF-300A | Ni60A+35WC-Ni | Ni60A+35WC-Ni | HRC65 | ≤600ºC | • Oxy-Acetylene, PTA, HVOF, APS, laser cladding, onwe-fluxing, okirikiri. • Waya ịbịaru wiil, agụba, pistons, impeller • Nguzogide iyi ka mma karịa Ni60 | |||||

| KF-300B | Ni60A+50WC-Co | Ni60A+50WC-Co | HRC65 | ≤600ºC | • Igwe brik • Mwepu sedimenti • ịghasa extrusion • Akụrụngwa ọrụ ugbo | |||||

| KF-300C | Ni60A+30WC-Co | Ni60A+30WC-Co | HRC65 | ≤600ºC | • Oxy-Acetylene, PTA, HVOF, APS, laser cladding, onwe-fluxing, okirikiri. • Waya ịbịaru wiil, agụba, pistons, impeller • Nguzogide iyi ka mma karịa Ni60 • Exelent urughuru na ike chere ihu abrasion na errosion iguzogide | |||||

| KF-300D | Nikel base Tugsten Carbide na-agbapụta onwe ya | Onye nwe ya | HRC65 | ≤600ºC | • Oxy-Acetylene, PTA, HVOF, APS, laser cladding, onwe-fluxing, okirikiri. • Waya ịbịaru wiil, agụba, pistons, impeller • Nguzogide iyi ka mma karịa Ni60 • Na-emegharị onwe ya • Exelent urughuru abrasion na corrosion iguzogide | |||||