MCrAlY Alloy nwere oke okpomọkụ na-eguzogide

Nkọwa

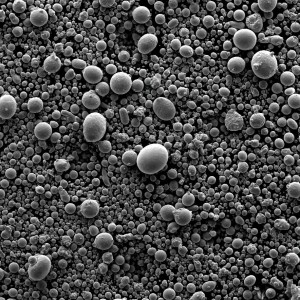

Ụdị:KF-301 KF-308 KF-309 KF-336 KF-337 KF-339… Ụdị: Atọmized gas

Njirimara ntụ ntụ:Ihe mejupụtara kemịkalụ: MCrAlY (M = Fe, Ni, or Co) Size: -45 +15 µm Ịdị Ọcha: ≥ 99.5%

Ngwa:A na-eji ntụ ntụ MCrAlY Alloy eme ihe na ngwa okpomọkụ dị elu n'ihi njirimara pụrụ iche ha.A na-ejikarị ha dị ka mkpuchi mkpuchi na mpịakọta ọla, mpịakọta sink na-ekpo ọkụ, na mpịakọta ọkụ ọgwụgwọ okpomọkụ.Tụkwasị na nke a, a na-eji ha na ụlọ ọrụ ikuku maka ịmepụta ihe ikuku gas, ihe mkpuchi ọkụ, na agụba igwe ikuku.

Njirimara nke MCrAlY Alloy

1.High Temperature Resistance: MCrAlY Alloy powders na-egosipụta nguzogide dị elu na okpomọkụ.Ngwongwo a na-eme ka ha dị mma maka ojiji na ngwa okpomọkụ dị elu dị ka turbin gas, ọkụ ọgwụgwọ okpomọkụ, na mpịakọta ígwè.

2.Antioxidant Properties: MCrAlY Alloy powders na-eguzogide oxidation na okpomọkụ dị elu, na-eme ka ha dị mma maka iji mee ihe na gburugburu ebe obibi siri ike ebe oxidation nwere ike ime, dị ka na gas turbines na okpomọkụ ọta.

3.Hot Corrosion Resistance: MCrAlY Alloy powders na-egosipụta ezigbo nguzogide na-ekpo ọkụ na-ekpo ọkụ, na-eme ka ha dị mma maka ngwa ngwa ebe a na-ekpuchi ihe ndị na-emerụ ahụ na gburugburu okpomọkụ.

4.Thermal Barrier Substrate: MCrAlY Alloy powders na-ejikarị eme ihe dị ka ihe mgbochi ihe mgbochi ọkụ n'ihi na ha na-eme ka ihe ọkụkụ dị mma na-eme ka ọ dịkwuo mma.A na-eji ha na-ejikọta ihe mkpuchi seramiiki iji chebe ihe dị n'okpuru ebe okpomọkụ dị elu.

N'ozuzu, MCrAlY Alloy powders bụ ihe ndị na-emepụta ihe na-egosipụta ihe ndị dị elu na-ekpo ọkụ, na-eme ka ha dị mma maka iji ngwa dị iche iche na-arụ ọrụ dị iche iche.Àgwà ha pụrụ iche, gụnyere nguzogide okpomọkụ dị elu, ihe ndị na-akpata antioxidant, nguzogide corrosion na-ekpo ọkụ, na ihe mgbochi mgbochi okpomọkụ, na-eme ka ha bụrụ nhọrọ a ma ama maka ngwa okpomọkụ dị elu.

Ngwaahịa ndị yiri ya

| Ụdị | Aha ngwaahịa | AMPERIT | METCO/AMDRY | WOKA | PRAXAIR | PAC |

| KF-301 | ||||||

| KF-308 | NiCrAlY | 9621 | ||||

| KF-309 | NiCoCrAlY | |||||

| KF-336 | CoCrAlSiY | |||||

| KF-337 | CoNiCrAlY | 9954 | ||||

| KF-339 | CoCrAlYTaSiC |

Nkọwapụta

| Ụdị | Aha ngwaahịa | Chemistry (wt%) | Isi ike | Okpomọkụ | Njirimara & Ngwa | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cr | Al | Y | Ta | Si | C | Co | Ni | |||||

| KF-301 | • APS, HVOF, ogbunigwe-egbe, okirikiri • akwa mkpuchi mkpuchi okpomọkụ | |||||||||||

| KF-308 | Nickel Chromium Aluminom Yttrium Alloy | 25 | 11 | 1 | Bal. | HRC 20-30 | ≤950ºC | • Mpịakọta ọla, mpịakọta sink na-ekpo ọkụ, mpịakọta ọkụ ọgwụgwọ okpomọkụ. • Aero engine agụba, gas turbine, okpomọkụ ọta | ||||

| KF-309 | Nickel Cobalt Chromium Aluminom Yttrium Alloy | 25 | 6 | 0.5 | 22 | Bal. | HRC 20-30 | ≤950ºC | • Igwe ọkụ dị elu, antioxidant. • Nguzogide corrosion na-ekpo ọkụ. • Thermal mgbochi mkpụrụ | |||

| KF-336 | Cobalt Chromium Aluminom Silicon Yttrium Alloy | 29 | 7 | 0.5 | 3 | Bal. | HRC 20-30 | ≤ 1000ºC | • Igwe ọkụ dị elu, antioxidant. • Hot corrosion eguzogide, mkpụrụ | |||

| KF-337 | Cobalt Chromium Aluminom Yttrium Alloy | 23 | 6 | 0.4 | Bal. | 30 | HRC 20-30 | ≤ 1050ºC | • Igwe ọkụ dị elu, antioxidant. • Hot corrosion eguzogide, thermal mgbochi mkpụrụ | |||

| KF-339 | Cobalt Chromium Aluminom Yttrium Alloy | 24 | 7.5 | 0.8 | 10 | 0.8 | 2 | Bal. | ≤ 1100ºC | • APS, HVOF, ogbunigwe-egbe, okirikiri • Mpịakọta ọla, mpịakọta ọkụ ọkụ na-ekpo ọkụ dị elu. • Aero igwe rotor agụba, ndu agụba na gas turbine agụba | ||