Cobalt Base Alloy na-eguzogide iyi na corrosion

Nkọwa

KF-3321 bụ ntụ ntụ ntụ ntụ dabere na cobalt nke nwere oke nguzogide iyi na oke ikuku oxidation.Ihe mejupụtara ya bụ cobalt, chromium, tungsten, nickel, silicon, na carbon, ọ nwekwara ike ịnwe obere aluminom, niobium, tantalum, na ihe ndị ọzọ alloy.

Njirimara ntụ ntụ

Nha urughuru:KF-3321 nwere oke nha nha nke -140 ruo +325 ntupu, nke na-eme ka ọ dabara maka ngwa dị iche iche ebe achọrọ nha nha dị mma.

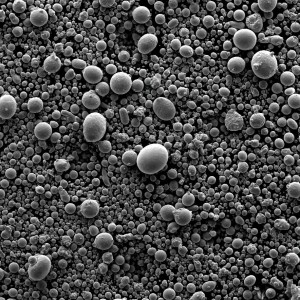

Ụdị:KF-3321 bụ ntụ ntụ atomized gas, nke pụtara na a na-emepụta ya site n'ịgbaze alloy wee jiri gas dị elu mee ya.Nke a na-eme ka ọdịdị ntụ ntụ dị okirikiri, nke na-enye ihe nrịbama dị mma na njupụta njupụta.

Ihe mejupụtara:KF-3321 bụ ntụ ntụ ntụ ntụ ntụ nke nwere oke cobalt, nke na-enye ya nguzogide iyi dị mma.Mgbakwunye nke chromium na tungsten na-eme ka nkwụsi ike ya dị elu na nguzogide oxidation dị elu.Nickel, silicon, na carbon na-enyekwu ike na nguzogide corrosion na alloy.

Ngwa

KF-3321 bụ ntụ ntụ ntụ ntụ na-agbanwe agbanwe nke enwere ike iji na ụlọ ọrụ dị iche iche maka ngwa ndị na-achọ nkwụsi ike na-eyi nke ọma na nguzogide oxidation dị elu.Ụfọdụ ngwa a na-ahụkarị gụnyere:

valves nrụgide okpomọkụ:KF-3321 dị elu na-eguzogide oxidation na-eme ka ọ bụrụ ihe dị mma maka valves nrụgide okpomọkụ.

Hụrụ ezé:KF-3321 na-eyi nguzogide na ike siri ike na-eme ka ọ dị mma maka iji ezé ezé, nke na-achọ ihe siri ike nke nwere ike iguzogide nrụgide na nkwụsị nke ịkpụ.

skru extrusion:KF-3321 na-eyi nkwụsi ike na oke okpomọkụ oxidation na-eme ka ọ bụrụ nhọrọ dị mma maka iji kposara extrusion, nke chọrọ ihe nwere ike iguzogide okpomọkụ dị elu na nrụgide nke usoro extrusion.

Yiri St12:KF-3321 nwere ihe ndị yiri ya na St12, obere carbon steel nke a na-ejikarị na ụlọ ọrụ ụgbọ ala.Otú ọ dị, KF-3321 nwere nkwụsi ike na-eyi nke ọma na nkwụsi ike oxidation dị elu karịa St12, na-eme ka ọ bụrụ nhọrọ dị elu maka ngwa ndị chọrọ nkwụsi ike dị elu na nkwụsi ike dị elu.

N'ozuzu, KF-3321 bụ ntụ ntụ ntụ ntụ na-arụ ọrụ dị elu nke na-enye nkwụsi ike na-eyi nke ọma na nguzogide oxidation dị elu.Ngwongwo ya dị iche iche na-eme ka ọ dị mma maka ngwa ngwa dị iche iche na ụlọ ọrụ dị iche iche.

Ngwaahịa ndị yiri ya

| Ụdị | Aha ngwaahịa | AMPERIT | METCO/AMDRY | WOKA | PRAXAIR | PAC |

| KF-331 | CoCrMoSi | 340 | 66/3002 | CO109/1247 | T400 | |

| KF-333 | CoCrMoSi | 342 | 68/3001/4800 | CO111/1248 | T800 | |

| KF-332 | CoCrWCNiSi | |||||

| KF-3321 | CoCrWCNiSi | |||||

| KF-3322 | CoCrWCNiSi | Yiri 344 | 4060 | CO106 1256 | 6 46 | |

| KF-3323 | CoCrWCNiSi | |||||

| KF-3324 | CoCrWCNiSi | 344 | 45 x40 | CO105 / CO285 | 90 | |

| KF-3325 | CoCrWCNiSi |

Nkọwapụta

| Ụdị | Aha ngwaahịa | Chemistry (wt%) | Isi ike | Okpomọkụ | Njirimara & Ngwa | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cr | W | C | Ni | Si | B | Mo | Co | |||||

| KF-331 | CoCrMoSi | 8 | 2.6 | 28 | Bal. | HRC 54 | ≤840ºC | • Yiri nguzogide, nguzogide ntu • Nguzogide corrosion | ||||

| KF-333 | CoCrMoSi | 17.5 | 3.4 | 35 | Bal. | HRC53 | ≤840ºC | • Yiri nguzogide, nguzogide ntu • Nguzogide corrosion | ||||

| KF-332 | CoCrWCNiSi | 25 | 7.5 | 0.8 | 10 | 1 | Bal. | HRC 30 | ≤840ºC | • oche valve • ibu • Akara • Yiri St1 | ||

| KF-3321 | CoCrWCNiSi | 30 | 4 | 1.5 | 3 | 1.4 | 4 | Bal. | HRC45 | ≤840ºC | • PTA, APS, HVOF, ihe mkpuchi laser, okirikiri • valvụ nrụgide dị elu, ezé hụrụ, kposara extrusion • Yiri St12 | |

| KF-3322 | CoCrWCNiSi | 30 | 4.5 | 1 | 3 | 1.4 | Bal. | HRC 40 | ≤840ºC | • PTA, APS, HVOF, ihe mkpuchi laser, okirikiri • Engine valves, elu okpomọkụ ụkpụrụ, turbo engine agụba • Yiri St6 • Nguzogide dị mma na oke okpomọkụ | ||

| KF-3323 | CoCrWCNiSi | 28 | 0.25 | 3 | 1 | 5.5 | Bal. | HRC55 | ≤840ºC | • agụba turbine • valvụ mmiri mmiri • oche valve | ||

| KF-3324 | CoCrWCNiSi | 25.5 | 7.5 | 0.5 | 10.5 | 1 | Bal. | HRC 30 | ≤840ºC | • Mkpụpụta ebu • Oghere ikuku gas | ||

| KF-3325 | CoCrWCNiSi | 21.0 | 5 | 0.1 | 1 | 1.6 | 2.4 | Bal. | HRC50 | ≤840ºC | • PTA, APS, HVOF, ihe mkpuchi laser, okirikiri • High okpomọkụ eyi mgbochi • valvụ ọgba tum tum • Na-emegharị onwe ya | |