NiAl cladding ntụ ntụ nwere ike njikọta siri ike

Nkọwa

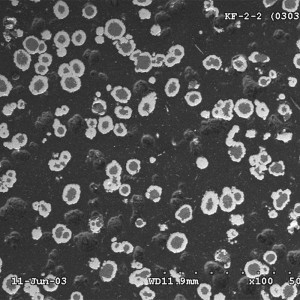

Anyị dị mpako iwebata ngwaahịa abụọ dabere na ntụ ntụ NiAl: KF-2 na KF-6.Ngwaahịa abụọ a na-eji nha dị iche iche nke ntụ ntụ NiAl ma nwee njirimara na ngwa pụrụ iche.

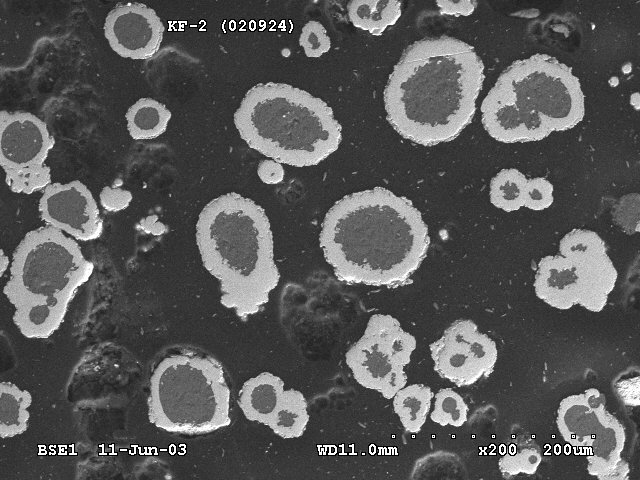

KF-2 na-eji NiAl82/18, nke nwere 82% Ni na 18% Al.Ngwaahịa a dabara adaba maka ngwa nwere oke okpomọkụ na-arụ ọrụ nke 650°C.Ọ na-enye mkpuchi siri ike, machinable, oxidation na-eguzogide, yana mkpuchi na-eyi ya na ihe ejikọtara onwe ya.A na-enwe mmeghachi omume exothermic mgbe niile n'oge usoro ịgba mmiri, nke na-ebute ike njikọ dị mma karịa ihe Ni5Al.KF-2 dabara adaba maka ịrụzi na nrụpụta machinable carbon steel na nchara na-eguzogide corrosion, a pụkwara iji ya mee ihe maka njikọta nke ceramik na ihe ndị nwere ike ime.

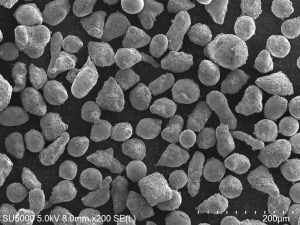

KF-6 na-eji NiAl95/5, nke nwere 95% Ni na 5% Al.Ngwaahịa a dabara adaba maka ngwa nwere oke okpomọkụ na-arụ ọrụ nke 800 Celsius ma enwere ike itinye ya site na iji ụzọ ịgba mmiri dị iche iche dịka ire ọkụ, APS, na HVOF.Ọ na-enyekwa mkpuchi siri ike, machinable, oxidation na-eguzogide, yana mkpuchi na-eguzogide ya na ihe ejikọtara onwe ya.A na-enwe mmeghachi omume exothermic mgbe niile n'oge usoro ịgba mmiri, na-ebute ike njikọ dị mma.A pụkwara iji KF-6 rụọ ọrụ maka ịrụzi na nrụpụta machinable carbon steel na nchara na-eguzogide corrosion, yana njikọta nke ceramik na ihe ndị nwere ike ime.

Na nchịkọta, ma KF-2 na KF-6 bụ ngwaahịa NiAl ntụ ntụ na-enye ike njikọ dị mma ma na-eyi nguzogide.KF-2, nke nwere obere pasent nke NiAl ntụ ntụ (NiAl82 / 18), dabara maka ngwa nwere oke ọrụ okpomọkụ nke 650 ° C, ebe KF-6, na pasent dị elu nke ntụ ntụ NiAl (NiAl95/5), nwere ike ijikwa okpomọkụ dị elu ruo 800 Celsius ma nwee ike itinye ya n'ọrụ site na iji usoro ịgba mmiri dị iche iche.Ngwaahịa abụọ a dị mma maka ịrụzi na nrụpụta machinable carbon steel na nchara na-eguzogide corrosion, yana maka njikọta nke ceramics na ihe ndị nwere ike ime.Nhọrọ n'etiti KF-2 na KF-6 dabere na ihe achọrọ ngwa ngwa yana oke okpomọkụ ọrụ achọrọ.

Ngwaahịa ndị yiri ya

| Ụdị | Aha ngwaahịa | AMPERIT | METCO/AMDRY | WOKA | PRAXAIR | PAC |

| KF-2 | NiAl82/18 | 404NS | ||||

| KF-6 | NiAl95/5 | 282 | 956450NS | NI-109 | 906 |

Nkọwapụta

| Ụdị | Aha ngwaahịa | Chemistry (wt%) | Isi ike | Okpomọkụ | Njirimara & Ngwa | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Al | W | Mo | Cr | Al2O3 | MoS2 | WC | C | Fe | Ni | |||||

| KF-2 | NiAl82/18 | 20 | Bal. | HRC 20 | ≤800ºC | • Ọkụ, APS, Max.okpomọkụ na-arụ ọrụ 650°C. • Okpokoro na machinable oxidation na-eguzogide ma na-eyi mkpuchi na-eguzogide ọgwụ. | ||||||||

| KF-6 | NiAl95/5 | 5 | Bal. | HRC 20 | ≤800ºC | • Ọkụ, APS, HVOF, Max.arụ ọrụ okpomọkụ 800C • Okpokoro na machinable oxidation na-eguzogide ma na-eyi mkpuchi na-eguzogide ọgwụ | ||||||||

| KF-20 | Ni-MoS₂ | 22 | Bal. | HRC 20 | ≤500ºC | • A na-eji ya maka akụkụ akara nke mbugharị na mgbanaka akara igwe • Enwere ike iji ya dị ka ihe mgbagha dị ala | ||||||||

| KF-21T | Ni-graphite 75/25 | 25 | Bal. | HRC 20 | ≤480ºC | • Ọkụ, Max.okpomọkụ na-arụ ọrụ 480 ° C 1. Ihe eji eme ihe nke turbo compressor • Ọdabara na nickel alloy na ígwè akụkụ • Ngwaahịa nwere nnukwu graphite dị mma maka akụkụ titanium na-enweghị ọnụ • Ọdịnaya graphite dị elu ga-eme ka ọrụ mmanu mmanu dịkwuo mma • Ọdịnaya nickel dị elu ga-eme ka mgbochi mbuze dịkwuo mma • Ngwaahịa ndị yiri ya dị iche iche n'ihi nkọwa OEM dị iche iche | ||||||||

| KF-22T/R | Ni-graphite 60/40 | 50 | Bal. | HRC 20 | ≤480ºC | |||||||||

| KF-21R | Ni-graphite 75/25 | 25 | Bal. | HRC 20 | ≤480ºC | |||||||||

| KF-45 | Ni-Al2O3 77/23 | 23 | Bal. | HRC 40 | ≤800ºC | • Ọkụ, APS, oge niile • Enwere ike iji ya na-agbaze crucible, njedebe akara n'elu na ebu elu dị ka ihe nchebe | ||||||||

| KF-56 | Ni-WC 16/84 | Bal. | 12 | HRC 62 | ≤400ºC | • Ọkụ, APS, oge niile • Iguzogide hammering, mbuze, abrasion na sliding abrasion | ||||||||

| KF-50 | Ni-WC10/90 | Bal. | 10 | HRC 62 | ≤400ºC | • Ọkụ, oge mgbe • Iguzogide hammering, mbuze, abrasion na sliding abrasion | ||||||||

| KF-91F | Fe-WC | 4 | 27 | 9.5 | Bal. | 5.5 | HRC 40 | ≤550ºC | • Ọkụ, APS, oge mgbe, Max.okpomọkụ na-arụ ọrụ 815°C. • Yiri ihe mkpuchi na-eguzogide ọgwụ, nke enwere ike iji maka ndozi breeki nke tank | |||||

| KF-110 | NiCr-Al 95/5 | 5 | 7.5 | Bal. | HRC 20 | ≤800ºC | • Ọkụ, APS, Max.okpomọkụ na-arụ ọrụ 980°C. • Na-efesa Plasma na njikọ onwe ya | |||||||

| KF-113A | NiCrAl-CoY2O3 | Cr+Al:20, Ni+Co:75 | HRC 20 | ≤900ºC | • APS, HVOF, oge mgbe, Max.okpomọkụ na-arụ ọrụ 980°C. • Ọ bụ ọdabara maka ndozi nke elu okpomọkụ bonding oyi akwa ma ọ bụ eyi / na-ekwesịghị ekwesị esichara akụkụ | |||||||||

| KF-133 | NiMoAl | 5 | 5 | Bal. | HRC 20 | ≤ 650ºC | • Njikọ onwe, mkpuchi siri ike nkịtị maka ibu ngwa • siri ike, na ezigbo nguzogide corrosion na mmetụta mmetụta • Ejiri maka akụkụ igwe, oche na-ebu na valvụ | |||||||

| KF-31 | Ni-Diatomite 75/25 | • Ọkụ, APS, oge mgbe, Max.okpomọkụ na-arụ ọrụ 650°C. • N'ihi na grindable akara mkpuchi, gụnyere ibughari akara akụkụ, grindable akara yiri mgbaaka, ala esemokwu ihe | ||||||||||||