Ụlọ ọrụ maka NiAl cladding ntụ ntụ

Ọrụ anyị bụ inye ndị ọrụ njedebe anyị na ndị ahịa ahịa ahịa dijitalụ kacha mma na asọmpi maka ụlọ ọrụ NiAl cladding powder, Lab anyị ugbu a bụ “National Lab of Diesel engine turbo technology” , na anyị nwere otu R&D nwere ahụmahụ na nnwale zuru oke. ihe owuwu.

Ọrụ anyị bụ ịnye ndị ọrụ njedebe anyị na ndị ahịa ahịa ngwa ahịa dijitalụ kacha mma dị elu yana asọmpi maka yaChina NiAl ntụ ntụ, Ihe mgbaru ọsọ anyị na-esote bụ ịgafe atụmanya nke onye ahịa ọ bụla site n'inye ọrụ ndị ahịa pụtara ìhè, mgbanwe mgbanwe na uru dị ukwuu.N'ihe niile, na-enweghị ndị ahịa anyị, anyị adịghị adị;na-enweghị obi ụtọ na afọ ojuju ndị ahịa, anyị na-ada.Anyị na-achọ n'ùkwù, Drop ship.Ị kwesịrị ịkpọtụrụ anyị ma ọ bụrụ na ị na-adọrọ mmasị anyị ngwa ahịa.Olileanya ka gị na gị niile na-azụ ahịa.Akwa mma na ngwa ngwa mbupu!

Nkọwa

Anyị dị mpako iwebata ngwaahịa abụọ dabere na ntụ ntụ NiAl: KF-2 na KF-6.Ngwaahịa abụọ a na-eji nha dị iche iche nke ntụ ntụ NiAl ma nwee njirimara na ngwa pụrụ iche.

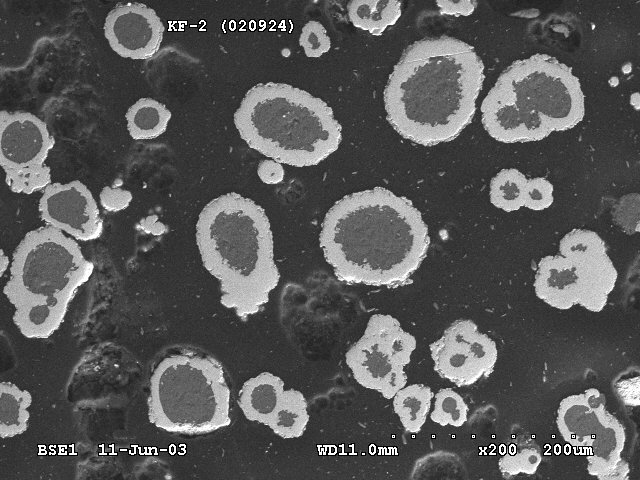

KF-2 na-eji NiAl82/18, nke nwere 82% Ni na 18% Al.Ngwaahịa a dabara adaba maka ngwa nwere oke okpomọkụ na-arụ ọrụ nke 650°C.Ọ na-enye mkpuchi siri ike, machinable, oxidation na-eguzogide, yana mkpuchi na-eyi ya na ihe ejikọtara onwe ya.A na-enwe mmeghachi omume exothermic mgbe niile n'oge usoro ịgba mmiri, nke na-ebute ike njikọ dị mma karịa ihe Ni5Al.KF-2 dabara adaba maka ịrụzi na nrụpụta machinable carbon steel na nchara na-eguzogide corrosion, a pụkwara iji ya mee ihe maka njikọta nke ceramik na ihe ndị nwere ike ime.

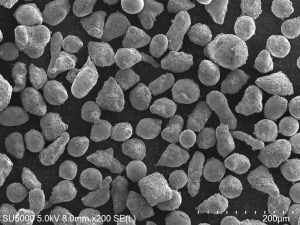

KF-6 na-eji NiAl95/5, nke nwere 95% Ni na 5% Al.Ngwaahịa a dabara adaba maka ngwa nwere oke okpomọkụ na-arụ ọrụ nke 800 Celsius ma enwere ike itinye ya site na iji ụzọ ịgba mmiri dị iche iche dịka ire ọkụ, APS, na HVOF.Ọ na-enyekwa mkpuchi siri ike, machinable, oxidation na-eguzogide, yana mkpuchi na-eguzogide ya na ihe ejikọtara onwe ya.A na-enwe mmeghachi omume exothermic mgbe niile n'oge usoro ịgba mmiri, na-ebute ike njikọ dị mma.A pụkwara iji KF-6 rụọ ọrụ maka ịrụzi na nrụpụta machinable carbon steel na nchara na-eguzogide corrosion, yana njikọta nke ceramik na ihe ndị nwere ike ime.

Na nchịkọta, ma KF-2 na KF-6 bụ ngwaahịa NiAl ntụ ntụ na-enye ike njikọ dị mma ma na-eyi nguzogide.KF-2, nke nwere obere pasent nke NiAl ntụ ntụ (NiAl82 / 18), dabara maka ngwa nwere oke ọrụ okpomọkụ nke 650 ° C, ebe KF-6, na pasent dị elu nke ntụ ntụ NiAl (NiAl95/5), nwere ike ijikwa okpomọkụ dị elu ruo 800 Celsius ma nwee ike itinye ya n'ọrụ site na iji usoro ịgba mmiri dị iche iche.Ngwaahịa abụọ a dị mma maka ịrụzi na nrụpụta machinable carbon steel na nchara na-eguzogide corrosion, yana maka njikọta nke ceramics na ihe ndị nwere ike ime.Nhọrọ n'etiti KF-2 na KF-6 dabere na ihe achọrọ ngwa ngwa yana oke okpomọkụ ọrụ achọrọ.

Ngwaahịa ndị yiri ya

| Ụdị | Aha ngwaahịa | AMPERIT | METCO/AMDRY | WOKA | PRAXAIR | PAC |

| KF-2 | NiAl82/18 | 404NS | ||||

| KF-6 | NiAl95/5 | 282 | 956450NS | NI-109 | 906 |

Nkọwapụta

| Ụdị | Aha ngwaahịa | Chemistry (wt%) | Isi ike | Okpomọkụ | Njirimara & Ngwa | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Al | W | Mo | Cr | Al2O3 | MoS2 | WC | C | Fe | Ni | |||||

| KF-2 | NiAl82/18 | 20 | Bal. | HRC 20 | ≤800ºC | • Ọkụ, APS, Max.okpomọkụ na-arụ ọrụ 650°C. • Okpokoro na machinable oxidation na-eguzogide ma na-eyi mkpuchi na-eguzogide ọgwụ. | ||||||||

| KF-6 | NiAl95/5 | 5 | Bal. | HRC 20 | ≤800ºC | • Ọkụ, APS, HVOF, Max.arụ ọrụ okpomọkụ 800C • Okpokoro na machinable oxidation na-eguzogide ma na-eyi mkpuchi na-eguzogide ọgwụ | ||||||||

| KF-20 | Ni-MoS₂ | 22 | Bal. | HRC 20 | ≤500ºC | • A na-eji ya maka akụkụ akara nke mbugharị na mgbanaka akara igwe • Enwere ike iji ya dị ka ihe mgbagha dị ala | ||||||||

| KF-21T | Ni-graphite 75/25 | 25 | Bal. | HRC 20 | ≤480ºC | • Ọkụ, Max.okpomọkụ na-arụ ọrụ 480 ° C 1. Ihe eji eme ihe nke turbo compressor • Ọdabara na nickel alloy na ígwè akụkụ • Ngwaahịa nwere nnukwu graphite dị mma maka akụkụ titanium na-enweghị ọnụ • Ọdịnaya graphite dị elu ga-eme ka ọrụ mmanu mmanu dịkwuo mma • Ọdịnaya nickel dị elu ga-eme ka mgbochi mbuze dịkwuo mma • Ngwaahịa ndị yiri ya dị iche iche n'ihi nkọwa OEM dị iche iche | ||||||||

| KF-22T/R | Ni-graphite 60/40 | 50 | Bal. | HRC 20 | ≤480ºC | |||||||||

| KF-21R | Ni-graphite 75/25 | 25 | Bal. | HRC 20 | ≤480ºC | |||||||||

| KF-45 | Ni-Al2O3 77/23 | 23 | Bal. | HRC 40 | ≤800ºC | • Ọkụ, APS, oge niile • Enwere ike iji ya na-agbaze crucible, njedebe akara n'elu na ebu elu dị ka ihe nchebe | ||||||||

| KF-56 | Ni-WC 16/84 | Bal. | 12 | HRC 62 | ≤400ºC | • Ọkụ, APS, oge niile • Iguzogide hammering, mbuze, abrasion na sliding abrasion | ||||||||

| KF-50 | Ni-WC10/90 | Bal. | 10 | HRC 62 | ≤400ºC | • Ọkụ, oge mgbe • Iguzogide hammering, mbuze, abrasion na sliding abrasion | ||||||||

| KF-91F | Fe-WC | 4 | 27 | 9.5 | Bal. | 5.5 | HRC 40 | ≤550ºC | • Ọkụ, APS, oge mgbe, Max.okpomọkụ na-arụ ọrụ 815°C. • Yiri ihe mkpuchi na-eguzogide ọgwụ, nke enwere ike iji maka ndozi breeki nke tank | |||||

| KF-110 | NiCr-Al 95/5 | 5 | 7.5 | Bal. | HRC 20 | ≤800ºC | • Ọkụ, APS, Max.okpomọkụ na-arụ ọrụ 980°C. • Na-efesa Plasma na njikọ onwe ya | |||||||

| KF-113A | NiCrAl-CoY2O3 | Cr+Al:20, Ni+Co:75 | HRC 20 | ≤900ºC | • APS, HVOF, oge mgbe, Max.okpomọkụ na-arụ ọrụ 980°C. • Ọ bụ ọdabara maka ndozi nke elu okpomọkụ bonding oyi akwa ma ọ bụ eyi / na-ekwesịghị ekwesị esichara akụkụ | |||||||||

| KF-133 | NiMoAl | 5 | 5 | Bal. | HRC 20 | ≤ 650ºC | • Njikọ onwe, mkpuchi siri ike nkịtị maka ibu ngwa • siri ike, na ezigbo nguzogide corrosion na mmetụta mmetụta • Ejiri maka akụkụ igwe, oche na-ebu na valvụ | |||||||

| KF-31 | Ni-Diatomite 75/25 | • Ọkụ, APS, oge mgbe, Max.okpomọkụ na-arụ ọrụ 650°C. • N'ihi na grindable akara mkpuchi, gụnyere ibughari akara akụkụ, grindable akara yiri mgbaaka, ala esemokwu ihe | ||||||||||||

Ọrụ anyị bụ inye ndị ọrụ njedebe anyị na ndị ahịa ahịa ahịa dijitalụ kacha mma na asọmpi maka ụlọ ọrụ NiAl cladding powder, Lab anyị ugbu a bụ “National Lab of Diesel engine turbo technology” , na anyị nwere otu R&D nwere ahụmahụ na nnwale zuru oke. ihe owuwu.

Ụlọ ọrụ makaChina NiAl ntụ ntụ, Ihe mgbaru ọsọ anyị na-esote bụ ịgafe atụmanya nke onye ahịa ọ bụla site n'inye ọrụ ndị ahịa pụtara ìhè, mgbanwe mgbanwe na uru dị ukwuu.N'ihe niile, na-enweghị ndị ahịa anyị, anyị adịghị adị;na-enweghị obi ụtọ na afọ ojuju ndị ahịa, anyị na-ada.Anyị na-achọ n'ùkwù, Drop ship.Ị kwesịrị ịkpọtụrụ anyị ma ọ bụrụ na ị na-adọrọ mmasị anyị ngwa ahịa.Olileanya ka gị na gị niile na-azụ ahịa.Akwa mma na ngwa ngwa mbupu!