Multi-arụ ọrụ mejupụtara cladding ntụ ntụ

Nkọwa

Nickel mkpuchi graphite mejupụtara ntụ ntụ bụ ihe mejupụtara ntụ ntụ na graphite ahụ dị ka isi ya na metal nickel dị ka mkpuchi elu ya, nke nwere ezigbo mmanu na nguzogide corrosion.Mgbe spraying thermal, ihe ahụ nwere ike ịmepụta ike dị elu, nguzogide oxidation, nkwụsi ike ọkụ na ọnụ ọgụgụ dị ala.

Nkọwapụta

| Ụdị | Aha ngwaahịa | Chemistry (wt%) | Isi ike | Okpomọkụ | Njirimara & Ngwa | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Al | W | Mo | Cr | Al2O3 | MoS2 | WC | C | Fe | Ni | |||||

| KF-2 | NiAl82/18 | 20 | Bal. | HRC 20 | ≤800ºC | • Ọkụ, APS, Max.okpomọkụ na-arụ ọrụ 650°C. • Okpokoro na machinable oxidation na-eguzogide ma na-eyi mkpuchi na-eguzogide ọgwụ. | ||||||||

| KF-6 | NiAl95/5 | 5 | Bal. | HRC 20 | ≤800ºC | • Ọkụ, APS, HVOF, Max.arụ ọrụ okpomọkụ 800C • Okpokoro na machinable oxidation na-eguzogide ma na-eyi mkpuchi na-eguzogide ọgwụ | ||||||||

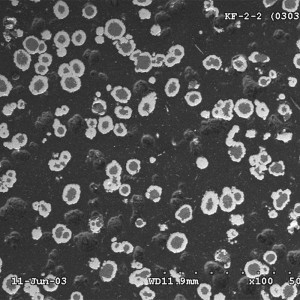

| KF-20 | Ni-MoS₂ | 22 | Bal. | HRC 20 | ≤500ºC | • A na-eji ya maka akụkụ akara nke mbugharị na mgbanaka akara igwe • Enwere ike iji ya dị ka ihe mgbagha dị ala | ||||||||

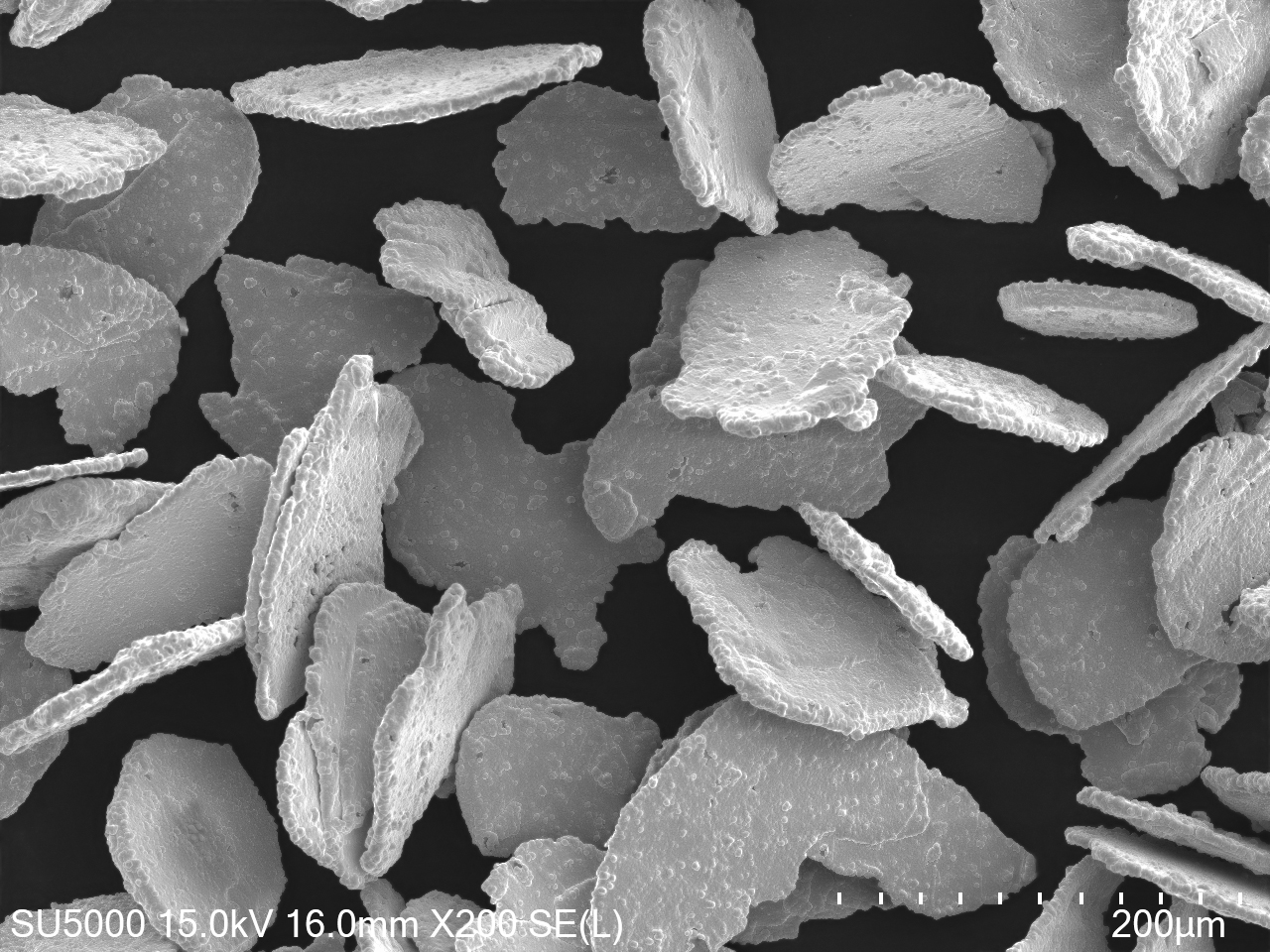

| KF-21T | Ni-graphite 75/25 | 25 | Bal. | HRC 20 | ≤480ºC | • Ọkụ, Max.okpomọkụ na-arụ ọrụ 480 ° C 1. Ihe eji eme ihe nke turbo compressor • Ọdabara na nickel alloy na ígwè akụkụ • Ngwaahịa nwere nnukwu graphite dị mma maka akụkụ titanium na-enweghị ọnụ • Ọdịnaya graphite dị elu ga-eme ka ọrụ mmanu mmanu dịkwuo mma • Ọdịnaya nickel dị elu ga-eme ka mgbochi mbuze dịkwuo mma • Ngwaahịa ndị yiri ya dị iche iche n'ihi nkọwa OEM dị iche iche | ||||||||

| KF-22T/R | Ni-graphite 60/40 | 50 | Bal. | HRC 20 | ≤480ºC | |||||||||

| KF-21R | Ni-graphite 75/25 | 25 | Bal. | HRC 20 | ≤480ºC | |||||||||

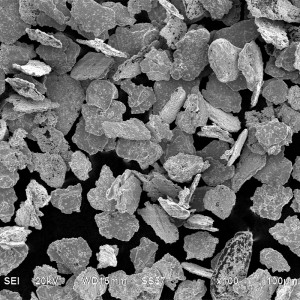

| KF-45 | Ni-Al2O3 77/23 | 23 | Bal. | HRC 40 | ≤800ºC | • Ọkụ, APS, oge niile • Enwere ike iji ya na-agbaze crucible, njedebe akara n'elu na ebu elu dị ka ihe nchebe | ||||||||

| KF-56 | Ni-WC 16/84 | Bal. | 12 | HRC 62 | ≤400ºC | • Ọkụ, APS, oge niile • Iguzogide hammering, mbuze, abrasion na sliding abrasion | ||||||||

| KF-50 | Ni-WC10/90 | Bal. | 10 | HRC 62 | ≤400ºC | • Ọkụ, oge mgbe • Iguzogide hammering, mbuze, abrasion na sliding abrasion | ||||||||

| KF-91F | Fe-WC | 4 | 27 | 9.5 | Bal. | 5.5 | HRC 40 | ≤550ºC | • Ọkụ, APS, oge mgbe, Max.okpomọkụ na-arụ ọrụ 815°C. • Yiri ihe mkpuchi na-eguzogide ọgwụ, nke enwere ike iji maka ndozi breeki nke tank | |||||

| KF-110 | NiCr-Al 95/5 | 5 | 7.5 | Bal. | HRC 20 | ≤800ºC | • Ọkụ, APS, Max.okpomọkụ na-arụ ọrụ 980°C. • Na-efesa Plasma na njikọ onwe ya | |||||||

| KF-113A | NiCrAl-CoY2O3 | Cr+Al:20, Ni+Co:75 | HRC 20 | ≤900ºC | • APS, HVOF, oge mgbe, Max.okpomọkụ na-arụ ọrụ 980°C. • Ọ bụ ọdabara maka ndozi nke elu okpomọkụ bonding oyi akwa ma ọ bụ eyi / na-ekwesịghị ekwesị esichara akụkụ | |||||||||

| KF-133 | NiMoAl | 5 | 5 | Bal. | HRC 20 | ≤ 650ºC | • Njikọ onwe, mkpuchi siri ike nkịtị maka ibu ngwa • siri ike, na ezigbo nguzogide corrosion na mmetụta mmetụta • Ejiri maka akụkụ igwe, oche na-ebu na valvụ | |||||||

| KF-31 | Ni-Diatomite 75/25 | • Ọkụ, APS, oge mgbe, Max.okpomọkụ na-arụ ọrụ 650°C. • N'ihi na grindable akara mkpuchi, gụnyere ibughari akara akụkụ, grindable akara yiri mgbaaka, ala esemokwu ihe | ||||||||||||